-

Notifications

You must be signed in to change notification settings - Fork 11

LaserCutterGerald

This page is for the larger laser cutter which incurs a £2 surcharge. You should only use it when your project needs the greater size and power.

| Nickname | Make | Model | Where | Manual | Issue Tracker | Status |

|---|---|---|---|---|---|---|

| "Gerald" | HPC Laser | Older version of LS1290 | Workshop | UserGuideSophia | Tool: Laser Cutter - Large (Gerald) | TBC |

See full safety information below

View Issues About This Equipment

See LaserCutting#Booking for details on how to book the laser. Here are quicklinks to the Gerald Calendar and the booking page where you can please book only one day at a time.

The DoES Liverpool Laser Cutter is an older version of this one from HPC Laser. The bed size is 1200mm by 900mm.

THESE INSTRUCTIONS ARE OUT OF DATE Volunteers to update them to match Lightburn would be most welcome. (Ideally helping out with this issue to update the laser-cutting area of the wiki in general)

- Turn laser on 5 minutes before cutting using the large red rotary lock switch (apols. on exact name of switch)

- Power up PC Shuttle Login with Bubblino password) and import your files. No wifi card on this machine

- DO NOT REMOVE THE RED USB DONGLE AND ENSURE THE COMPUTER IS PLUGGED IN TO THE LASER BY USB: this should be by default now

- Turn on the extraction system

- Click "Laser Output" from the drop down menus and arrange your layers in the order you want

- Double click on "Layers" to change options "Cut" or "Engrave" and ensure the Power and speed settings are what you require

- Remember this is a more high wattage laser; but more power does not necssarily mean cutting better; At a certain temperature an over powered cut will become a less efficient cut. Refer to the settings below.

- Make sure layers are in the correct order, i.e. etching before cutting

- Make sure you have specified the correct settings for each layer: cut vs engrave, and power & speed settings.

- Place material in laser cutter and then focus laser, top point of red tinted acrylic "ruler" should point into the top of the groove on the laser focus head.

- Use the Up and Down buttons on the cutter to raise or lower the cutting bed.

- Click "Laser Output", and "Download" in software menus, "Delete All" and "Download Current"

- If you Save your ECP cut file (usually a good idea) the file name will appear on the lasercutter LCD display.

- Click "Test" button to make sure your cut will fit on your material.

- Close lid

- Press Start to start cutting.

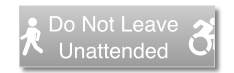

The laser cutter, if not used and monitored properly, carries a continuous risk of igniting the work piece being cut.

- Workshop Safety

- See also: LaserCutterTraining

| Hazard | Who might be harmed an how? | What is already being done? |

|---|---|---|

| Fire | Laser cutter user, other people in the workshop | Must be attended while in use. Users trained before use, or only under direct supervision of another trained user. |

| Burn, skin or eye damage | Laser cutter user, other people in the workshop | Only to be used after induction. Operated in a reflection enclosed box. Safety interlock on the main door (laser will not fire unless the door is closed). |

VERY IMPORTANT!!! Ensure you wait at LEAST 2 minutes _preferably more to let volatile fumes to be extracted. Gerald is less efficient at extraction due to the much larger cutting volume. Otherwise you risk the health of yourself and others in the workshop. MDF and Ply fumes are NOT good for you even if they smell nice. You will be breathing wood dust and glue or carbon monoxide and formaldehyde in Acrylic. If you do accidentally open the machine before full extraction please close the lid immeadiately open the window further and step away from the machine and advise others to do so until fumes clear.

SERIOUSLY: Please consider your health and those around you. With great Power(80W) comes great responsibility.

Some LaserCutterTraining information.

You can simply lift the steel slatted bed to access cut material that falls through the bed but please ENSURE THE LASER HEAD IS PUSHED TO THE EDGE OF THE BED OTHERWISE YOU RISK DAMAGE TO CUTTING HEAD at best requiring re-calibration, at worst seriously damaging gerald. Be careful replacing the bed, dropping it into the frame can affect the level and cause cutting problems.

There is a separate page on LaserCutterInkscape.

For power and speed settings for materials cut on Sophia see CutEtchSettingsGerald General details of materials suitable for laser cutting and suppliers are listed in LaserMaterials.

You cannot cut vinyl on a laser cutter as it releases chlorine gas which is both noxious and corrosive so is ** EXTREMELY dangerous & potentially fatal** to inhale and seriously damages the laser cutter. You also can not cut metal on our particular laser cutter as it is not powerful enough and reflects the beam, damaging the cutter.

Quick Links: Website • Groups • Rooms • Equipment • Issue Tracker • Discussion Group • Image Credits

☝️ Filter all pages above!

(Full search available on the top left of page)

WiFi: DoES Liverpool, password: decafbad00

- Wiki Home

- Making

- Get involved

- In The Space

- Bank and PayPal Details

or