-

-

Notifications

You must be signed in to change notification settings - Fork 35

Home

A fabricatable machine is a computer-controlled fabrication machine that can be made using a standard set of existing computer-controlled machines; with minimal use of speciality parts, processes or skills. The type of machines include CNC-milling, lasercutter, and 3d-printers.

We want to enable individuals and communities to build their own production machines, to expand their own capabilities. Build more machines to increase production, build cheaper to increase availability, or build specialized machines tailored for specific purposes.

The project consists of three main levels: Individual fabricatable modules make linear and rotary fabricatable axes which again can be compiled into complete fabricatable machines.

You can download the files for individual machines or a big .zip file with everything. If you improve on the designs you can share them back with a pull request

Feel free to expand and improve all sections of this project and wiki.

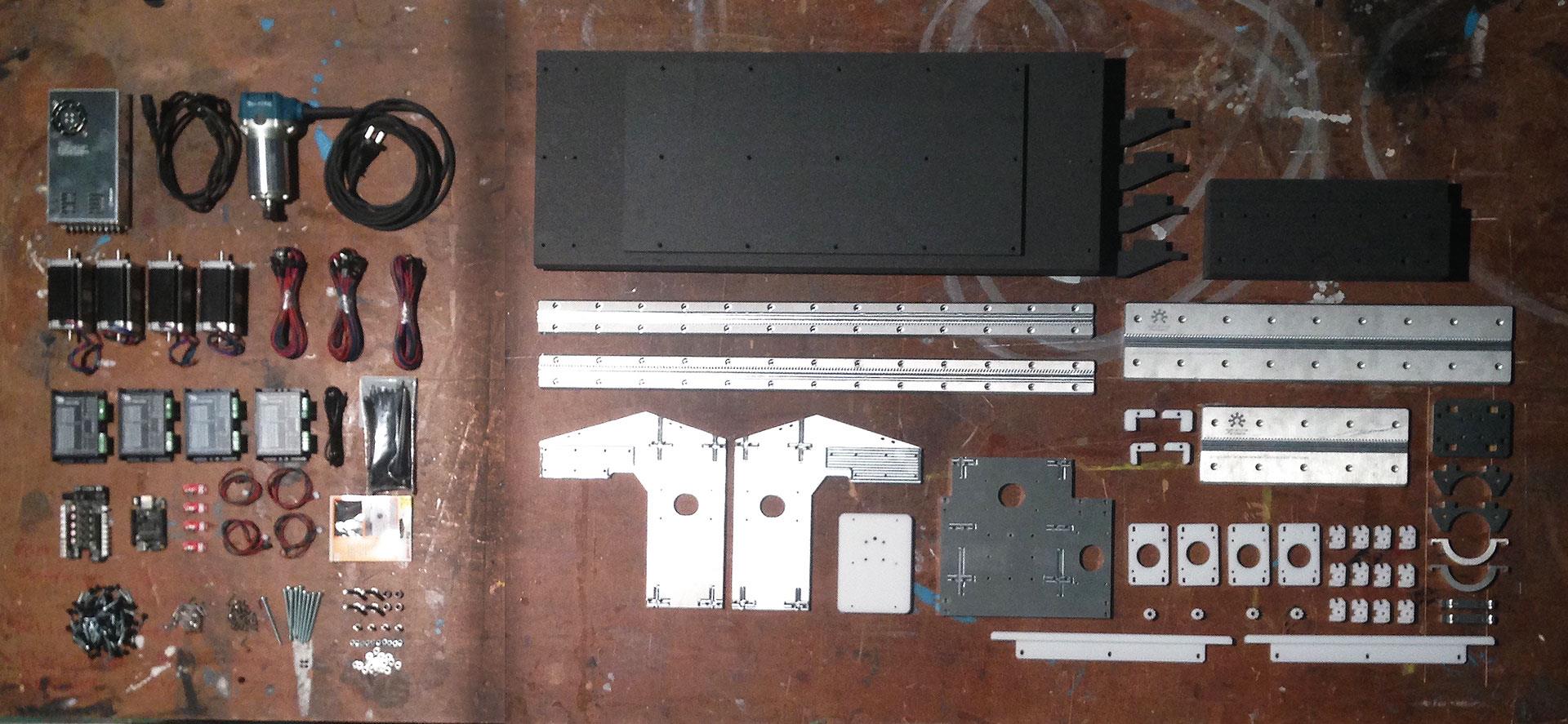

Storebought parts to the left VS self fabricated part to the right. These parts are for Hank, a retired machine.

Storebought parts to the left VS self fabricated part to the right. These parts are for Hank, a retired machine.

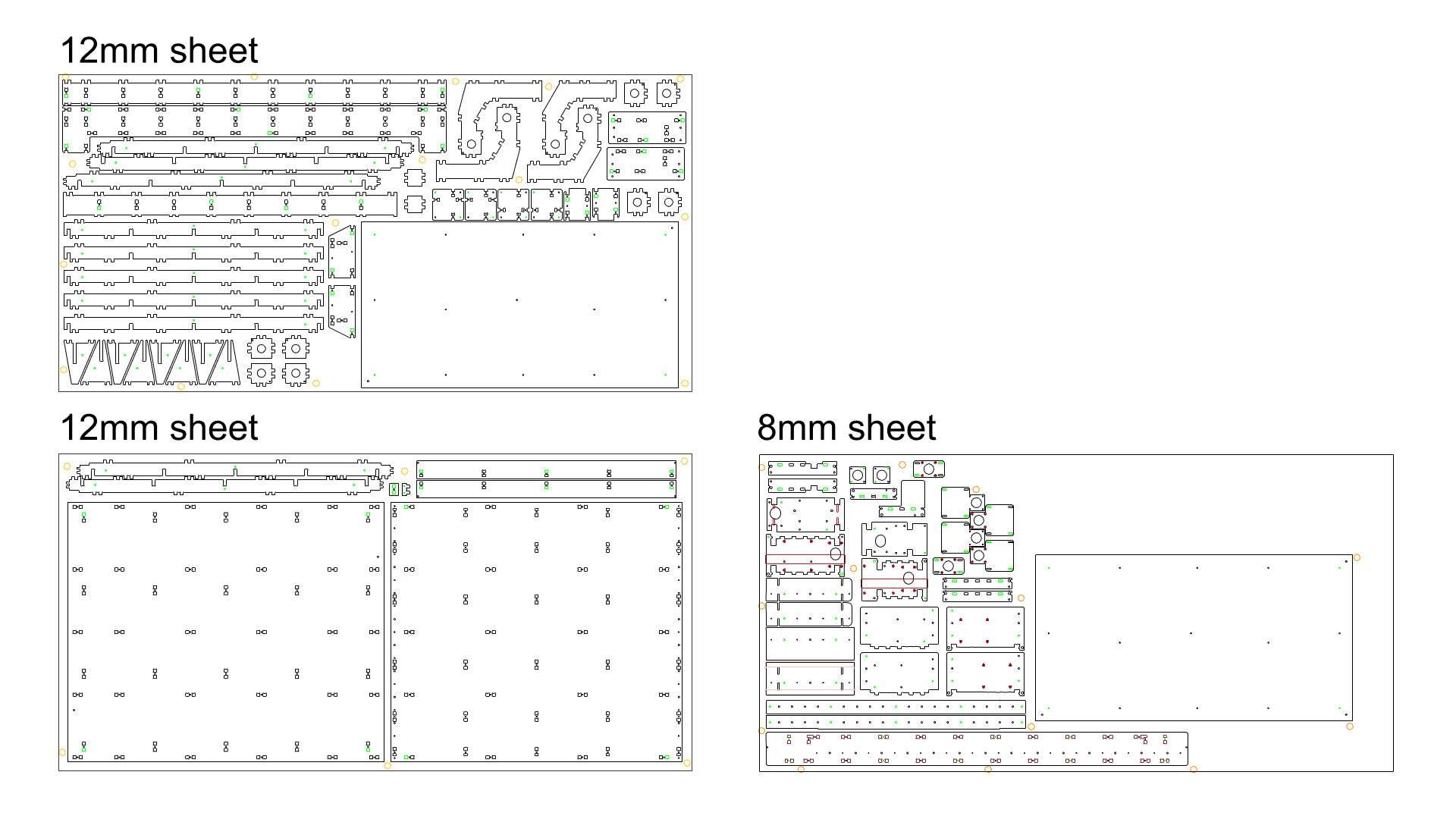

Example of cutsheets for CNC milling. These are the parts need for making a wood Humprhey.

Example of cutsheets for CNC milling. These are the parts need for making a wood Humprhey.

So you want to fab your own machine? Awesome!

Fabricatable machines has a wide variety for you to choose from and each one has its own version. There is a lot of info and files in this repo, so here is guide to getting started:

For instance the Z axis from a machine like Hattori or Humphrey. We like valchromat a lot. It is a little denser than normal mdf and looks pimp.

We buy most of our electronic components from Aliexpress. You find links in the documentation page of the individual machines.

Step 4 - give feedback on the issues page and upload new or improved files

Self fabricated rack, pinion, rails and machine on Humphrey v1

Self fabricated rack, pinion, rails and machine on Humphrey v1