Releases: prusa3d/Prusa-Firmware

3.9.0 BETA Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary:

- Linear Advance 1.5

- Screen brightness adjustment

- Filament sensor status detection

- New G-codes sorting (last modified)

- MK3 Toggle and Translations

- MMU2S selector blade activated

- Show current Z offset in reset dialog before first layer calibration

- Independent belt test

- Unknown Z position

- Other changes

- Fixed bugs

- Known issues

- GitHub templates

WARNING: In this release, the power panic feature is not working properly with the Original Prusa i3 MK3S. If you are experiencing frequent power surges, please consider waiting for the next release.

Detailed description

This firmware release is focused mainly on pull requests from the community. Since there are many changes, we have decided to release the firmware in the BETA version. Note that at this stage it is not recommended to use the firmware on a production printer!

We would like to thank everyone, who participated in this release!

New Features

Linear Advance 1.5

#1909

One of the biggest contributions from the community is the support for Linear Advance 1.5, which is also backward compatible with the previous version. In case you have a G-code with Linear Advance 1.0, the printer will analyze the code and convert the values.

This graph is showing the function used for converting LA 1.0 and 1.5

Screen brightness adjustment (MK3/MK3S only)

Starting this release the selected printers are capable of adjusting the brightness of the screen, which is convenient if the printer is used in a darker environment. The user can adjust the following parameters:

Screen Backlight ON

Screen Backlight OFF

In the menu head to Settings -> Brightness

Update: Note that this feature is available for printers manufactured in the second half of 2019. For older printers, you have to replace the LCD screen and also in some cases the Einsy board (you must have Einsy 1.1a or newer). Selected parts can be obtained in the e-shop, spare parts section.

Filament sensor status detection

This is feature is still in development and the goal is a better recognition of the filament sensor status. The printer is continuously measuring the voltage (Support > Voltages) and based on the value it recognizes three states:

- Inserted filament: approx. 0.3 V - 0.5 V

- No filament: approx. 4.2 V - 4.6 V

- Disconnected sensor: approx. 4.8 V - 5.0 V

The sensor has to be at least version rev0.4 (red PCB).

New G-codes sorting (last modified)

Until now the G-codes on the SD card were sorted based on the time when each file was created and the system was ignoring any modification to it. Starting with 3.9.0-beta the files are sorted properly according to the last modification.

MK3 Toggle and Translations

The code responsible for displaying the toggle menus was rewritten in order to enable faster switching and lower the requirements on the CPU. Toggle menus were previously hardwired into the firmware, this is now changed to enable easier translations.

MMU2S selector blade activated

Part of the MMU2S unit is a selector equipped with a blade, which if needed will cut the tip of the filament unloaded from the extruder. Until now the cutting function wasn't enabled.

To start using this function, make sure you have:

- Firmware 1.0.6 installed in the MMU2S unit

- Firmware 3.9.0-beta installed in the MK3S/MK2.5S

The printed parts for the selector were updated to provide a better grip of the blade and will be available for download soon.

Show current Z offset in reset dialog before first layer calibration

In the case of rerunning the First Layer Calibration, the printer first checks if the value of Live Adjust Z is stored in the EEPROM. Before the process is started, the user is asked to confirm, whether the calibration should start from the current value of the Live Adjust Z or reset this value to zero (factory defaults).

Independent belt test

#1060 #1937

The belt test is evaluating if proper tension in the belts is achieved and until now the status was refreshed only after running the self-test. Based on the feedback from the community it is now as a standalone test available at all times. To run it, go to the Menu->Support->Belt status.

Unknown Z

In a situation when the printer doesn't know the exact Z-axis position (e.g. after the power on) a question mark is displayed on the screen next to the Z coordinate.

Language dictionary size increased

The original design of the memory blocks in the EEPROM expected files smaller than 64 KB. However, while increasing the number of functions and respective text strings, the size of some language dictionaries required a bigger space allocation. After successfully refactoring this part of the code, this limit is no longer present.

Other changes

Sheet's name displayed on the status screen

#2146 #2093

The name of the currently selected steel sheet is now displayed on the home screen for easier orientation.

Enable print fan to speed up while “waiting for a cooldown” procedure

#1704

While waiting for a hotend cooldown, the printer activates the print fan in order to speed up the cooling phase.

Safer moves in Z-axis, if the position is unknown

#1768

In a situation when the printer doesn't know the exact Z-axis position (e.g. after the power on) a stall guard is activated to stop the movement immediately if the obstacle (heatbed) is detected.

M350 for all axes

#2057

The G-code M350 (micro-stepping) is now implemented for all axis, previously only for the extruder.

Bug fixes

Heater running and extruder not parked at print's end

In some scenarios at the end of the print, the heater was still running and the extruder wasn't parked at the correct location.

F.I.N.D.A. sensor always triggered

The F.I.N.D.A. sensor on some MMU2S units was always triggered, even if no filament was present.

Infinite Loop

G-code M601 was in specific scenarios causing an endless loop.

Fixed planner for OctoprintMMU2S power panic improved

Fixed planner for Octoprint MMU2S after a power panic, which caused incorrect reconnection to the printed object.

Known Issues

Power panic

Power panic - as noted in the beginning the power panic function isn't working in this release.

Filament sensor for MK3

The optical sensor isn't detecting the filament correctly at all times.

Linear Advance e-jerk value

The conversion function between LA 1.5 and 1.0 doesn't refresh e-jerk value. As a result, the print might be up to 30 % slower.

Filament runout

The filament runout for MMU2S doesn't work properly.

Stop print

Stop print during print with MMU2S causes a filament runout.

GitHub templates

We have improved the procedure while creating an issue on the GitHub, the page is now equipped with several templates to address all possible issues.

- BUG

- ENHANCEMENT

- FEATURE REQUEST

- QUESTIONS

While starting a new issue please take your time, select and fill in the most appropriate one. It will speed up the entire process.

3.8.1 Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary

- Calibration using multiple filament types

- Repeated First layer calibration settings

- Fan error on Octoprint

- Incorrect mode display MK2.5S & MK2.5

- New Live Adjust Z shortcut

- Move Z shortcut adjustment

- Translations corrections

- Other bug fixes

A detailed description

This changelog is a summary of the previous release (RC1) with additional bug fixes introduced in this release.

Calibration using multiple filament types

Until now the First Layer Calibration was possible only using a PLA. However, the textured and smooth PEI sheets perform better (improved filament adhesion), if the calibration is done based on the used material. Starting this release user can choose from the following expanded material list: PLA, PET, ASA, ABS, HIPS, PP, FLEX. #2117 This feature was also requested by the Prusa community and we would like to thank you for the valuable feedback.

Repeated First layer calibration settings

In case the First Layer Calibration is started again, the printer always used the previously saved value of Z-offset. This can cause an issue if the recalibration is done while changing the thinner textured for the thicker smooth sheet and thus the nozzle might be too low.

With the firmware 3.8.1 RC1, the printer always asks, whether to continue with the previously saved value or reset the offset to zero. #2222

Fan error on Octoprint

If a Fan error occurred during the print using an Octoprint, then the user was unable to continue with the print even if the issue was resolved. This is now fixed and the print can be restored.

Incorrect mode display MK2.5S & MK2.5

In some scenarios, after the printer reset, an incorrect Mode was displayed (High Power instead of Stealth). This bug is now fixed and the mode is displayed correctly.

New Live Adjust Z shortcut

Right after the mesh bed levelling as soon as the print is started, the user can adjust from the menu the height between the tip of the nozzle and the steel sheet (Live Adjust Z) to ensure the filament is properly squished in the printing surface.

Now, there is a new shortcut to access this function. Long press the rotation knob to enter the adjustment menu. The function is available only during the print between 0-2 mm of height.

The Live Adjust Z shortcut is allowed in the following menus (during the print only):

- Info screen

- Main menu

- Tune

- Support

Move Z shortcut adjustment

To move the Z-axis up or down, the user can either choose this option from the menu or long-press the rotation knob. Because this shortcut is now shared with the Live Adjust Z, the Move Z is available only before the mesh bed leveling starts and after the print is finished.

Previously, it was also possible to use the shortcut during the print, this is now disabled. #2165 #2101

The Move Z shortcut is allowed in the following menus:

- Info screen

- Main menu

- Preheat

- Print from SD

- Settings

- Temperature

- Select language

- Support

Translations corrections

For this release, the firmware, which is translated into seven languages, was checked by Prusa in-house native speakers improving the consistency with English original, 3D printing terminology and readability on the printer's screen.

Other bug fixes

Calibration of the Z-axis wasn't working properly for the Stealth mode, now the calibration is always performed in the Normal Mode.

3.8.1 RC1 Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary

- Calibration using multiple filament types

- Repeated First layer calibration settings

- Fan error on Octoprint

- Incorrect mode display MK2.5S & MK2.5

- New Live Adjust Z shortcut

- Move Z shortcut adjustment

- Translations corrections

A detailed description

Calibration using multiple filament types

Until now the First Layer Calibration was possible only using a PLA. However, the textured and smooth PEI sheets perform better (improved filament adhesion), if the calibration is done based on the used material. Starting this release user can choose from the following expanded material list: PLA, PET, ASA, ABS, HIPS, PP, FLEX. #2117 This feature was also requested by the Prusa community and we would like to thank you for the valuable feedback.

Repeated First layer calibration settings

In case the First Layer Calibration is started again, the printer always used the previously saved value of Z-offset. This can cause an issue if the recalibration is done while changing the thinner textured for the thicker smooth sheet and thus the nozzle might be too low.

With the firmware 3.8.1 RC1, the printer always asks, whether to continue with the previously saved value or reset the offset to zero. #2222

Fan error on Octoprint

If a Fan error occurred during the print using an Octoprint, then the user was unable to continue with the print even if the issue was resolved. This is now fixed and the print can be restored.

Incorrect mode display MK2.5S & MK2.5

In some scenarios, after the printer reset, an incorrect Mode was displayed (High Power instead of Stealth). This bug is now fixed and the mode is displayed correctly.

New Live Adjust Z shortcut

Right after the mesh bed levelling as soon as the print is started, the user can adjust from the menu the height between the tip of the nozzle and the steel sheet (Live Adjust Z) to ensure the filament is properly squished in the printing surface.

Now, there is a new shortcut to access this function. Long press the rotation knob to enter the adjustment menu. The function is available only during the print between 0-2 mm of height.

The Live Adjust Z shortcut is allowed in the following menus (during the print only):

- Info screen

- Main menu

- Tune

- Support

Move Z shortcut adjustment

To move the Z-axis up or down, the user can either choose this option from the menu or long-press the rotation knob. Because this shortcut is now shared with the Live Adjust Z, the Move Z is available only before the mesh bed leveling starts and after the print is finished.

Previously, it was also possible to use the shortcut during the print, this is now disabled. #2165 #2101

The Move Z shortcut is allowed in the following menus:

- Info screen

- Main menu

- Preheat

- Print from SD

- Settings

- Temperature

- Select language

- Support

Translations corrections

For this release, the firmware, which is translated into seven languages, was checked by Prusa in-house native speakers improving the consistency with English original, 3D printing terminology and readability on the printer's screen.

3.8.0 Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary:

- Steel sheet profiles

- Nozzle diameter setup

- Preliminary checks

- Firmware onscreen notification

- Revised sound warnings

- Heatbed noise at 110 V (60 Hz)

- Crash detection fixes

- Addition of the ASA material

- Beta testers

A detailed description:

This changelog is a summary of the previous releases (RC1 & RC2) with additional detailed information regarding the steel sheet profiles feature.

Steel sheet profiles

Magnetic heatbed on MK3S/MK2.5S enables using multiple steel sheets for continuous printing. However, due to a different thickness of various sheets (textured vs smooth PEI), each sheet requires individual First layer calibration. Starting with this release, we are adding a feature, which will store the settings for up to 8 sheets. You can then easily switch between the sheets (profiles) and the printer will load the stored values.

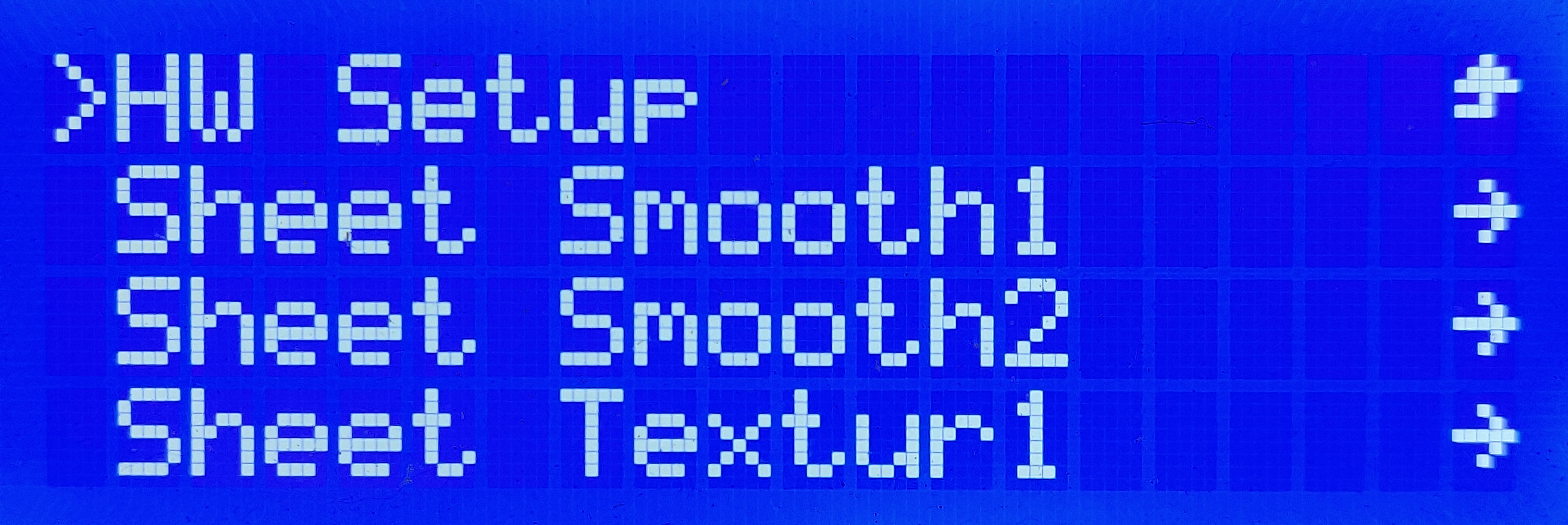

There is a new section of the settings menu called “HW setup”, which will allow you to individually setup each sheet and some other parameters, which are described later in this release log.

To set up the individual sheet profiles, please head to the Settings -> HW setup -> Steel Sheets (Fig. 1)

There are currently eight sheet profiles (Fig. 2) available with predefined, but fully customizable names. Note that each sheet has the same factory settings.

For each sheet you can do the following:

- Select - confirms the selection of the sheet, which will then become the default

- First layer calibration - takes you through the first layer calibration process, this calibration must be performed on each sheet (Fig. 3)

- Rename - enables you to change the name, up to seven characters (Fig. 4)

- Reset - sets the values back to the factory defaults

As soon as two or more profiles are configured, you will be able to quick-toggle between them directly from the main menu (Fig. 5)

When upgrading firmware to version 3.8.0, the existing Z offset value from First Layer Calibration is copied to the first steel sheet.

Nozzle diameter setup

This an initial release of this function. We need to finish the coding on the PrusaSlicer side in order to fully enable it. By default, all Original Prusa i3 printers are shipped with the 0.4mm nozzle. In case you change the nozzle, you can set the correct diameter in the printer's menu (see Settings -> HW setup -> Nozzle d.). The printer will then compare the stored value of the nozzle diameter with parametres in the G-code. If there is a mismatch, you will be informed to prevent a print failure.

Preliminary checks

Similarly to the previous feature, this one also requires an update of the PrusaSlicer. Once this is done, the printer will check multiple parameters in order to warn you about incompatible print settings. Before a print is started, the printer will compare parameters stored in the memory with the G-code. Checked values are nozzle diameter, the model of the printer and firmware version. Checks can be adjusted in Settings -> Checks.

For each controlled parameter, users can set three levels of warnings:

none - check is turned off, the user won't receive any notification

warn - a warning message will be displayed on the screen, user can continue with the print

strict - a warning message will be displayed on the screen, the user can't continue until the issue is fixed, print is aborted

Firmware onscreen notification

The firmware onscreen notification about the availability of the new version no longer waits for the user response, which prevents the print from starting. The timeout is now set to 30 seconds, the printer then proceeds with the print.

Revised sound warnings

In the previous firmware release, there was an option to disable sound warnings completely by choosing the [None] option. Due to safety reasons, this release no longer offers this value. User can choose between [Loud|Once|Silent|Assist], where the last value is newly introduced for visually impaired users.

By selecting the Assist sound mode, the printer enables accessibility feature and plays a different sound while scrolling through the menu and at the end of the menu.

Heatbed noise at 110 V (60 Hz)

There were several reports regarding noise from the heatbed when the printer was connected to a 110 V (60 Hz) network. In the current release, the rising and falling edges of the pulse-width modulation (PWM) are adjusted to fix the unwanted noise. Previously, the PWM was falling from 30 Hz to 15 Hz and as a result, the PSU started to switch between high and low power mode, which caused the "clicking". Also, while printing at extremely high speeds over a USB connection, the altered PWM affected the planner, resulting in a slower print. This is now fixed as well.

Crash detection fixes

The crash detection feature can be turned off in the printer's menu, however, in the RC1 release, it stopped working for the Normal mode. Even when set to [OFF], the printer still detected the crash (issue #2094). The part responsible for crash detection was revised and fixed.

In very rare cases, prior to the printing phase, a false crash was detected and then while printing the first layer the printer skipped some longer segments of the G-code (above 30 mm). As a result, the extruder moved according to the next G-code instruction. We've adjusted the behaviour of the crash detection for the first layer, which solved this issue.

Addition of the ASA material

ASA is newly introduced to the Original Prusa i3 printers and can be considered a true successor to ABS. Starting this release, ASA is included in the preheat menu with support in the PrusaSlicer. Learn more about ASA in our latest article ASA Prusament is here!

Prusa Firmware beta testers group

Our beta testing group is running already for three months and over 450 users joined our ranks. As we promised in the beginning, we will reward the most active users, who help us to improve the firmware.

We would like to thank Wavexx and Leptun, both are valued long-term testers. We appreciate all the help provided and decided to send an Original Prusa i3 MK3S kit as a courtesy.

3.8.0 RC2 Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary:

- Power panic fix

- Heatbed noise at 110 V (60 Hz)

- Crash detection fixes

- Addition of the ASA material

A detailed description:

Power panic fix

In the previous release (RC1), the power panic function was broken and didn't work properly. This issue was caused by a new feature (still in development), which further lowers the noise made by the printer. Now, the code is fixed and power panic works as expected.

Heatbed noise at 110 V (60 Hz)

There were several reports regarding noise from the heatbed when the printer was connected to a 110 V (60 Hz) network. In the current release, the rising and falling edges of the pulse-width modulation (PWM) are adjusted to fix the unwanted noise. Previously, the PWM was falling from 30 Hz to 15 Hz and as a result, the PSU started to switch between high and low power mode, which caused the "clicking". Also, while printing at extremely high speeds over a USB connection, the altered PWM affected the planner, resulting in a slower print. This is now fixed as well.

Crash detection fixes

The crash detection feature can be turned off in the printer's menu, however, in the RC1 release, it stopped working for the Normal mode. Even when set to [OFF], the printer still detected the crash (issue #2094). The part responsible for crash detection was revised and fixed.

In very rare cases, prior to the printing phase, a false crash was detected and then while printing the first layer the printer skipped some longer segments of the G-code (above 30 mm). As a result, the extruder moved according to the next G-code instruction. We've adjusted the behavior of the crash detection for the first layer, which solved this issue.

Addition of the ASA material

ASA is newly introduced to the Original Prusa i3 printers and can be considered a true successor to ABS. Starting this release, ASA is included in the preheat menu with support in the PrusaSlicer. The ASA option is missing in the "Load filament" menu and will be added in the next release. Learn more about ASA in our latest article ASA Prusament is here!

3.8.0 RC1 Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary:

- Steel sheet profiles

- Nozzle diameter setup

- Preliminary checks

- Firmware onscreen notification

- Revised sound warnings

- Beta testers

WARNING: In this release, the power panic feature is not working properly with the Original Prusa i3 MK3S. If you are experiencing frequent power surges, please consider waiting for the next release. Since this is a testing release we DO NOT recommend flashing this firmware to a production printer.

A detailed description:

Steel sheet profiles

Magnetic heatbed on MK3S/MK2.5S enables using multiple steel sheets for continuous printing. However, due to a different thickness of various sheets (textured vs smooth PEI), each sheet requires individual First layer calibration. Starting with this release, we are adding a feature, which will store the settings for up to 3 sheets. You can then easily switch between the sheets (profiles) and the printer will load the stored values.

To set up the individual sheet profiles, please head to the Settings -> HW setup. There are currently three sheet profiles available.

For each sheet you can do the following:

- Select - confirms the selection of the sheet, which will then become default

- First layer calibration - takes you through the first layer calibration process

- Rename - enables you to change the name, up to seven characters

- Reset - sets the values back to the factory defaults

As soon as two or more profiles are configured, you will be able to quick-toggle between them in the main menu. A detailed description of the behaviour will be released with the final version of the firmware 3.8.0.

Nozzle diameter setup

This an initial release of this function. We need to finish the coding on the PrusaSlicer side in order to fully enable it. By default, all Original Prusa i3 printers are shipped with the 0.4mm nozzle. In case you change the nozzle, you can set the correct diameter in the printer's menu (see Settings -> HW setup -> Nozzle d.). The printer will then compare the stored value of the nozzle diameter with parametres in the G-code. If there is a mismatch, you will be informed to prevent a print failure.

Preliminary checks

Similarly to the previous feature, this one also requires an update of the PrusaSlicer. Once this is done, the printer will check multiple parameters in order to warn you about incompatible print settings. Before a print is started, the printer will compare parameters stored in the memory with the G-code. Checked values are nozzle diameter, the model of the printer and firmware version. Checks can be adjusted in Settings -> Checks.

For each controlled parameter, users can set three levels of warnings:

none - check is turned off, the user won't receive any notification

warn - a warning message will be displayed on the screen, user can continue with the print

strict - a warning message will be displayed on the screen, the user can't continue until the issue is fixed, print is aborted

Firmware onscreen notification

The firmware onscreen notification about the availability of the new version no longer waits for the user response, which prevents the print from starting. The timeout is now set to 30 seconds, the printer then proceeds with the print.

Revised sound warnings

In the previous firmware release, there was an option to disable sound warnings completely by choosing the [None] option. Due to safety reasons, this release no longer offers this value. User can choose between [Loud|Once|Silent|Assist], where the last value is newly introduced for visually impaired users.

By selecting the Assist sound mode, the printer enables accessibility feature and plays a different sound while scrolling through the menu and at the end of the menu.

Others

PWM adjusted to reduce printer noise from heatbed and PSU.

Known issues

The power panic feature is not working properly for the MK3S printer. We are currently investigating all scenarios when the system is unable to recover the print after a power surge.

Prusa Firmware beta testers group

Our beta testing group is running already for two months and over 400 users joined our ranks. As we promised in the beginning, we will reward the most active users, who help us to improve the firmware.

The first reward goes to Yuri D'Elia aka Wavexx who is a valued long-term tester. We appreciate all the help provided and decided to send an Original Prusa i3 MK3S kit as a courtesy.

3.7.2 Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary:

- Protection against multiple power panics

- Autonomous fan self-test

- Incorrect firmware flashing protection

- Min. temp safety trigger

- Enforced fan check

- Filament runout delay fix

- Extruder position after fan error fix

- Text format correction on Live adjust Z screen

- Display target temperature at PID calibration screen

A detailed description of changes:

Protection against multiple power panics (for MK3S/MK3/MMU2S/MMU2)

In case of a rare scenario where the printer was in the process of recovering from the first power panic and a second occurred, it might have caused an error and fail the print. Starting this release, the printer is protected against multiple quickly-following power panic scenarios and it should always recover.

Autonomous fan self-test

In the previous release, the user had to assist during the fan test. Now, the self-test is fully automatic. Printer spins up each fan from low to the max RPM and measures the values. Since both fans on the extruder have a different range, it is possible to detect, whether they are connected to the correct socket on the board and whether the fan is able to reach its max RPM.

Incorrect firmware flashing protection

Each of our Original Prusa i3 printers requires a slightly different firmware. The system now checks whether you are flashing the correct hex file. For the future releases, if a wrong file is used, the user is warned during the reboot after the firmware is flashed. We are working on a feature in the PrusaSlicer, which will warn you before the entire process starts.

Min. temp safety trigger

In the case of min. temp scenario, the printer used to run the G-code on the background, but didn't execute any movements nor the filament loading, then displayed min. temp error. The new firmware will immediately restart the printer as soon as min. temp scenario occurs. This is a safety feature to prevent the printer from overheating as min. temp is mostly caused by damaged thermistor reading incorrect temperature values. After the restart, the user can start the print again, but please check whether the print starts correctly.

Enforced fan check

Previously during the "fan error" message, the user was allowed to continue printing without fixing the issue, this no longer possible. Until the error fixed by the user (e.g. removing the jammed filament from the fan), the print is paused. This is a safety feature preventing possible damage to the printer.

Others:

- Filament runout delay fix

- Extruder position after fan error fix

- Text format correction on Live adjust Z screen

- Display target temperature at PID calibration screen

Known issue for the future release:

Shifted print after a power panic

During our internal tests, it was discovered that after multiple power panics in a row, the printer sometimes slightly shifts the print up in the Z axis (tenths of millimeters) during the recovery. Although this is a very unlikely situation in real-world conditions, we are working on a fix.

Prusa Firmware beta testers group

Are you an experienced user, who wants to join our insider testing group? We are looking for skilled users, who are willing to help to improve the firmware. You will be given our most recent versions and provide feedback on any bugs or errors you might encounter. For the most active testers, we have prepared attractive rewards ;)

3.7.2 RC1 Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary:

- Improving the behavior of repeated power panic

- Automatic fan self-test

- Checking the correct firmware version for the printer

- Mintemp fix

- Filament runout delay fix

- Extruder position after fan error fix

- Text format correction on Live adjust Z screen

- Display target temperature at PID calibration screen

Detailed description of changes:

Improving the behavior of repeated power panic

Fixed several problematic situations when power panic is triggered in progress power panic recovery

Automatic fan self-test:

The self-test is more robust, fan control is automatic

Checking the correct firmware version for the printer:

Protection against unwanted uploading of the wrong type of firmware to the printer.

Mintemp fix:

If a mintemp error has occurred before, the printer just ignored the processed gcode, now the printer is restarted. Indeed, Mintemp can point to a serious mistake and thus restart printer is a safer solution.

Known issues:

Fan check

If a user does not correct the cause of the fan error and continues printing, the display does not show an error.

However, the printer does not continue to heat and expects user intervention.

Repeated power panic

In some cases of repeated power panic, printing may start a few tenths of a millimeter higher than it should.

We are working on solving these particular problems.

NEW Prusa Firmware beta testers group

A good printer needs great firmware, we at Prusa Research are trying to create such firmware and would like to reach out to a group of users who are also interested in developing our firmware. If you belong to this group, then sign up. The most active of you will be rewarded.

3.2.3 firmware for Prusa i3 MK2/S/MMU

This firmware 3.2.3 is the final version of firmware version 3.2.2 RC1 for MK2/S, which contains important safety improvement in preheat error and also chosen features from MK3S branch.

Summary:

- Preheat error improved

- Improved temperature regulation

- Remaining time estimation

- Adjustable beeper notifications

- Incomplete file check updated

- G-code fixes (M27, M110, M115)

A detailed description of changes (compared to 3.2.2-RC1):

Stop after Pause fix

We found and fixed a bug that led to improper print termination when Pause print and Stop print commands were executed in quick succession.

NEW Prusa Firmware beta testers group

A good printer needs great firmware, we at Prusa Research are trying to create such firmware and would like to reach out to a group of users who are also interested in developing our firmware. If you belong to this group, then sign up. The most active of you will be rewarded.

3.7.1 Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary:

- Rambo board overheating fix

- Enabled watchdog for MK2.5S & MK2.5

- Octoprint MMU load failed fix

- Bed preheat error fix

- SPI flash error is not blocking the printer anymore

- IR-sensor self-test fail message added

- Menu items text overflowing fix

- Linearity correction not saved to EEPROM fix

A detailed description of changes (compared to 3.7.0-RC1):

Watchdog fix

In the firmware version 3.7.1 we added on MK2.5 and MK2.5S printers a watchdog for better safety. In firmware 3.7.1 RC1 the watchdog was only added to MK2.5.