3.8.0 Firmware for MK3, MK3S, MK2.5 and MK2.5S

Summary:

- Steel sheet profiles

- Nozzle diameter setup

- Preliminary checks

- Firmware onscreen notification

- Revised sound warnings

- Heatbed noise at 110 V (60 Hz)

- Crash detection fixes

- Addition of the ASA material

- Beta testers

A detailed description:

This changelog is a summary of the previous releases (RC1 & RC2) with additional detailed information regarding the steel sheet profiles feature.

Steel sheet profiles

Magnetic heatbed on MK3S/MK2.5S enables using multiple steel sheets for continuous printing. However, due to a different thickness of various sheets (textured vs smooth PEI), each sheet requires individual First layer calibration. Starting with this release, we are adding a feature, which will store the settings for up to 8 sheets. You can then easily switch between the sheets (profiles) and the printer will load the stored values.

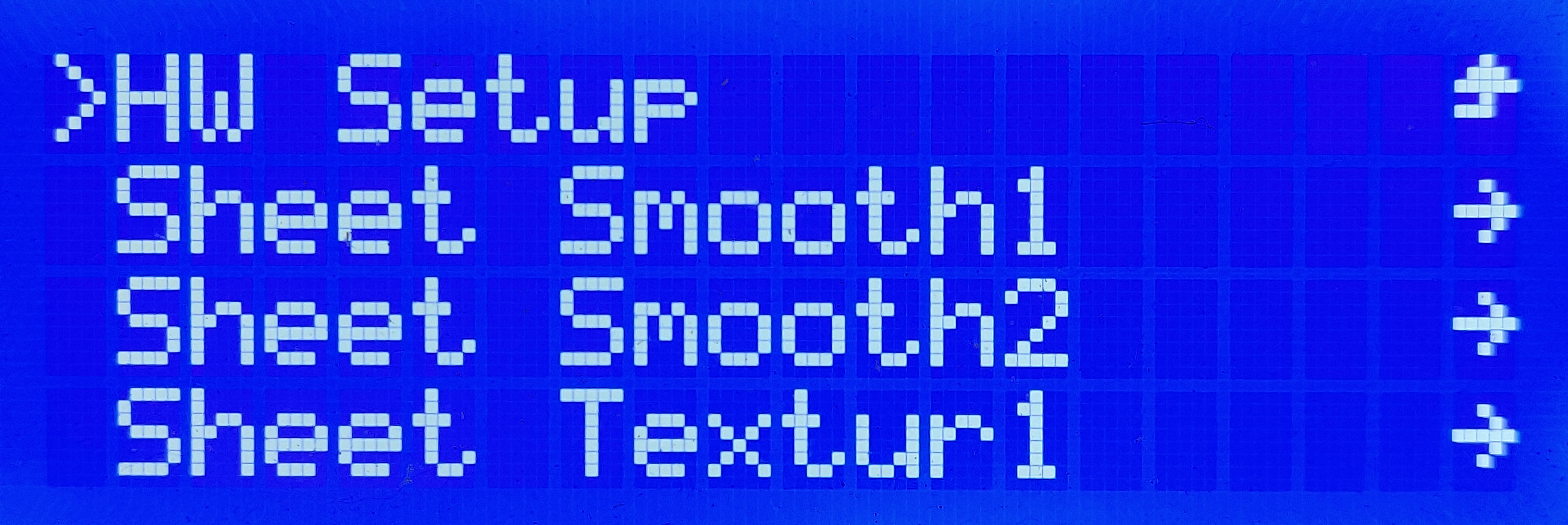

There is a new section of the settings menu called “HW setup”, which will allow you to individually setup each sheet and some other parameters, which are described later in this release log.

To set up the individual sheet profiles, please head to the Settings -> HW setup -> Steel Sheets (Fig. 1)

There are currently eight sheet profiles (Fig. 2) available with predefined, but fully customizable names. Note that each sheet has the same factory settings.

For each sheet you can do the following:

- Select - confirms the selection of the sheet, which will then become the default

- First layer calibration - takes you through the first layer calibration process, this calibration must be performed on each sheet (Fig. 3)

- Rename - enables you to change the name, up to seven characters (Fig. 4)

- Reset - sets the values back to the factory defaults

As soon as two or more profiles are configured, you will be able to quick-toggle between them directly from the main menu (Fig. 5)

When upgrading firmware to version 3.8.0, the existing Z offset value from First Layer Calibration is copied to the first steel sheet.

Nozzle diameter setup

This an initial release of this function. We need to finish the coding on the PrusaSlicer side in order to fully enable it. By default, all Original Prusa i3 printers are shipped with the 0.4mm nozzle. In case you change the nozzle, you can set the correct diameter in the printer's menu (see Settings -> HW setup -> Nozzle d.). The printer will then compare the stored value of the nozzle diameter with parametres in the G-code. If there is a mismatch, you will be informed to prevent a print failure.

Preliminary checks

Similarly to the previous feature, this one also requires an update of the PrusaSlicer. Once this is done, the printer will check multiple parameters in order to warn you about incompatible print settings. Before a print is started, the printer will compare parameters stored in the memory with the G-code. Checked values are nozzle diameter, the model of the printer and firmware version. Checks can be adjusted in Settings -> Checks.

For each controlled parameter, users can set three levels of warnings:

none - check is turned off, the user won't receive any notification

warn - a warning message will be displayed on the screen, user can continue with the print

strict - a warning message will be displayed on the screen, the user can't continue until the issue is fixed, print is aborted

Firmware onscreen notification

The firmware onscreen notification about the availability of the new version no longer waits for the user response, which prevents the print from starting. The timeout is now set to 30 seconds, the printer then proceeds with the print.

Revised sound warnings

In the previous firmware release, there was an option to disable sound warnings completely by choosing the [None] option. Due to safety reasons, this release no longer offers this value. User can choose between [Loud|Once|Silent|Assist], where the last value is newly introduced for visually impaired users.

By selecting the Assist sound mode, the printer enables accessibility feature and plays a different sound while scrolling through the menu and at the end of the menu.

Heatbed noise at 110 V (60 Hz)

There were several reports regarding noise from the heatbed when the printer was connected to a 110 V (60 Hz) network. In the current release, the rising and falling edges of the pulse-width modulation (PWM) are adjusted to fix the unwanted noise. Previously, the PWM was falling from 30 Hz to 15 Hz and as a result, the PSU started to switch between high and low power mode, which caused the "clicking". Also, while printing at extremely high speeds over a USB connection, the altered PWM affected the planner, resulting in a slower print. This is now fixed as well.

Crash detection fixes

The crash detection feature can be turned off in the printer's menu, however, in the RC1 release, it stopped working for the Normal mode. Even when set to [OFF], the printer still detected the crash (issue #2094). The part responsible for crash detection was revised and fixed.

In very rare cases, prior to the printing phase, a false crash was detected and then while printing the first layer the printer skipped some longer segments of the G-code (above 30 mm). As a result, the extruder moved according to the next G-code instruction. We've adjusted the behaviour of the crash detection for the first layer, which solved this issue.

Addition of the ASA material

ASA is newly introduced to the Original Prusa i3 printers and can be considered a true successor to ABS. Starting this release, ASA is included in the preheat menu with support in the PrusaSlicer. Learn more about ASA in our latest article ASA Prusament is here!

Prusa Firmware beta testers group

Our beta testing group is running already for three months and over 450 users joined our ranks. As we promised in the beginning, we will reward the most active users, who help us to improve the firmware.

We would like to thank Wavexx and Leptun, both are valued long-term testers. We appreciate all the help provided and decided to send an Original Prusa i3 MK3S kit as a courtesy.